Computer vision technology is a powerful AI tool that can understand, interpret and analyze images and videos. By integrating computer vision into new or existing infrastructure, businesses can automate manual inspection processes. V-Soft Digital worked with a public research university in the Northeast to deploy a computer vision system to automatically detect defects in manufacturing components. Learn more in the video above or the recap below.

The Need for Automation

The manufacturing department within this university was looking to adopt smart manufacturing technologies and automate many of their manual, outdated processes. These old processes were costing more time and money for the department than necessary and it was time for a change. University leaders turned to V-Soft Digital for an advanced technology solution that would save the organization time and money, while still maintaining and improving overall accuracy.

How Computer Vision Solved the Problem

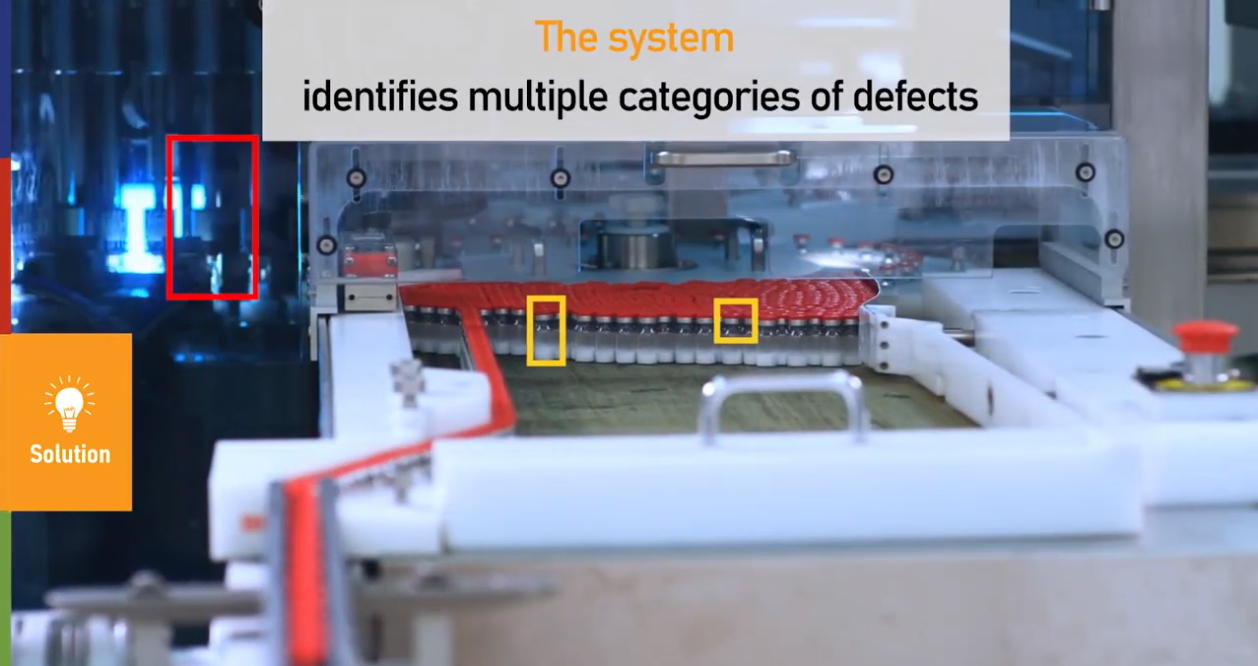

V-Soft Digital deployed a computer vision system to support automated defect detection on industrial products such as steel piping for the oil and gas industry and even automated the analysis of defects and their categorization. With this technology in place, the department saw significant improvements within their industrial lab. The system has the ability to identify multiple categories of defects, enhance image processing, and capture digital certificates of defect details, including location and size.

This automation solution increased defect detection accuracy by 17%, which saved the university both time and money otherwise wasted on overlooked defects. Repair downtime was reduced by 10% with a more proactive analysis in place, and manual inspection was altogether eliminated in the process. This lead to an overall savings of $150K per production line.

Technologies Applied

- Internet of Things (IoT)

- Computer Vision

- GreenGrass

- Industrial Camera Systems

- AWS Lambda

- AWS SageMaker

- S3 Buckets