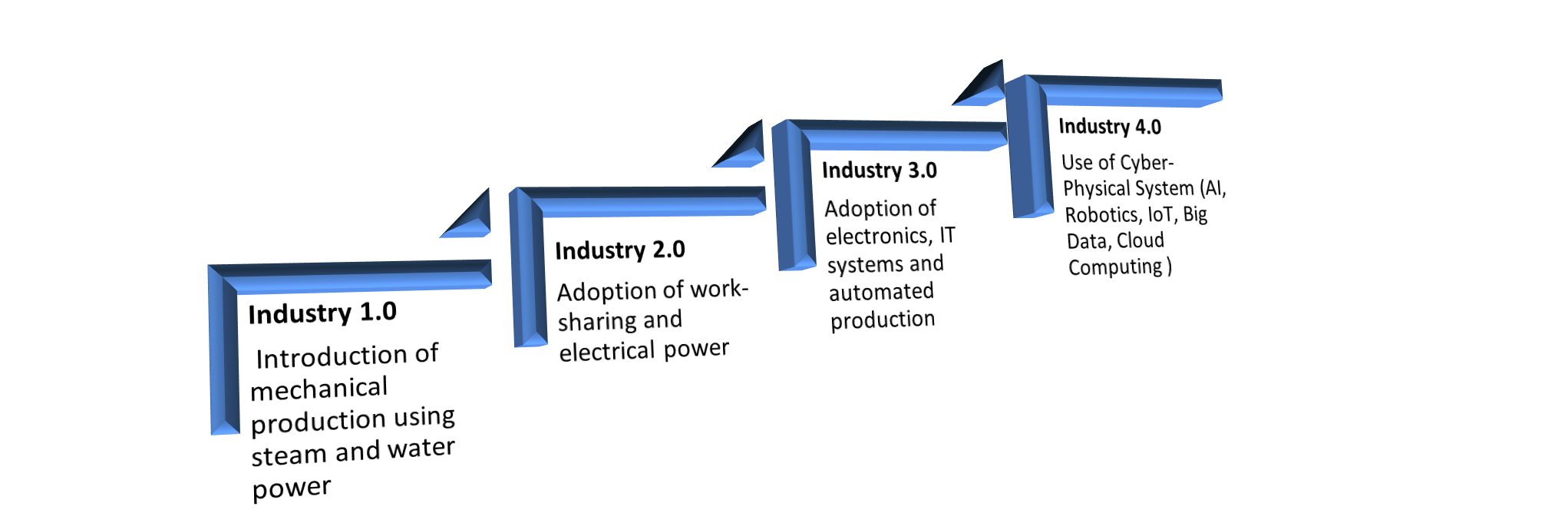

While we are at the cusp of Industry 4.0, figuring out how artificial intelligence, robotics, the Internet of Things, big data, and machine learning are impacting businesses, technologists are heralding the arrival of the next industrial revolution or Industry 5.0 in the future. This is consistent with how industries have changed over time. Since the first industrial revolution began in the 18th century, technology has played an important role in redefining and reinventing itself. The first industrial revolution saw the introduction of mechanized production facilities using water and steam power which later gave way to electrical power. Industry 3.0 saw electronics and IT systems play a key role in automating production in manufacturing units.

Automation and robotics have been around for a while although on a limited scale and only in specific industries. Industry 4.0 leveraged technological trends categorized under the label “cyber-physical systems” to transform manufacturing rapidly. The use of robots which was largely seen in specific sectors such as automotive industries has now expanded to nearly all other manufacturing sectors riding the wave of rapid technological advancement. Robots are now preferred for dull, dangerous, and dirty jobs, and have even improved the quality of products, increased the speed of production, helped in the mass customization of products, and do all this at a much-reduced cost. In this blog, we will highlight the major transformation of industry 4.0 to 5.0.

Lights-out Manufacturing

The continuing evolution of the industry has led to lights-out or dark factories that are fully automated and operate autonomously without any human supervision. They are called dark factories because the robots work 24/7 and do not require lights or air-conditioning to function. The responsibility of the human workers is to ensure that the operations run smoothly and not necessarily be a part of the actual manufacturing process. These lights-out manufacturing setups may be rare, but they highlight the fact that automation technologies are an important part of Industry 4.0 and 5.0 and are being deployed across sectors. At the same time, the very fact that human workers are being able to be replaced by robots reveals that Industry 4.0 setups expect human workers to work with machines without applying creativity and craftsmanship.

What to Expect from Industry 5.0?

Mass Personalization with a Human Touch

Customization of products is very much part of the Industry 4.0 paradigm but going forward in industry 5.0 there is going to be a demand for mass personalization of products. Consumers would be willing to pay more for products that bear the mark of human craftsmanship which makes the products unique and give the impression of having been made for that particular consumer. Furthermore, it may not always be about consumers wanting to feel special and express their identity through personalized products, in sectors such as the healthcare and medical device industry, personalization would mean a matter of life and death of an individual patient. Human involvement in the manufacturing process would once again satisfy the demand for mass personalization. This does not mean that the use of robots in manufacturing would be discontinued or reduced, rather, technologists see a future where human-robot co-working would be prevalent.

Collaborative Robots

Cobots or collaborative robots are robots that work alongside human workers, sharing the same workspace and assisting them. These robots can do the heavy lifting in the manufacturing process while the creative control over the product remains in the hands of the human workers. For instance, manufacturing gadgets such as smartphones without automation would be nearly impossible for mass production but consumers would still want their smartphones to be personalized. With collaborative robots, the human workers would have the tools to automate the labour-intensive parts of the process ensuring speed and accuracy while retaining creative control over the manufacturing process which is necessary for personalization.

AI and Automation

Outside manufacturing other departments would also benefit from the continued development in the field of artificial intelligence. Using AI tools, processes in finance and accounting, sales and marketing, operations, HR, and supply chain management can be automated to improve efficiency as well as free up human workers for more strategic work. Customer service is already witnessing transformation brought about by automation and AI such as the adoption of intelligent chatbots for customer interaction. This trend is likely to increase bringing further improvement in the field of customer service.

Conclusion

Industrial revolutions from the first to the fourth have seen a natural progression with more work and control being given to machines in each wave. Industry 5.0 is likely to disrupt this as it aims to bring human creativity and craftsmanship back into manufacturing but with automation and collaboration with robots to aid and support workers. This would not only help meet consumer demands but also provide workers with more meaningful work and give them more skills.